The evolution of weather-resistant coating technologies has fundamentally transformed the reliability and longevity of outdoor mirror installations across diverse environmental conditions. Modern coating systems represent sophisticated material science achievements that protect reflective surfaces from environmental degradation while maintaining optical clarity and structural integrity throughout extended service periods. Understanding these technologies enables facility managers and engineering professionals to select optimal coating solutions that maximize installation value while minimizing maintenance requirements.

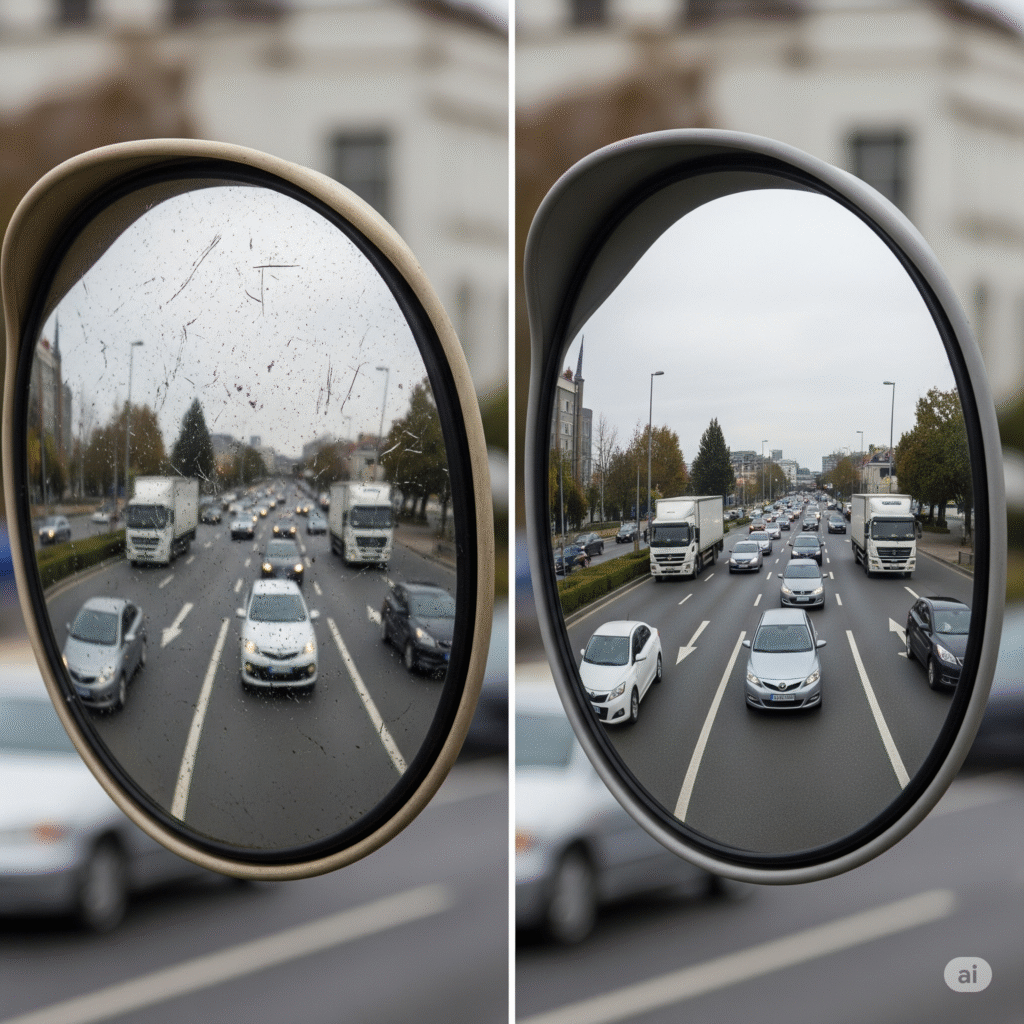

Traditional mirror installations suffered from rapid degradation when exposed to outdoor environments, with standard glass and aluminum backing systems proving inadequate against moisture infiltration, temperature cycling, and chemical exposure. Contemporary coating technologies address these limitations through advanced polymer chemistry, nano-scale engineering, and multi-layer protection systems that provide comprehensive environmental resistance. The performance improvements achieved through modern coatings often extend mirror service life by 300-500 percent compared to unprotected installations.

The economic implications of proper coating selection extend throughout the entire lifecycle of mirror installations, affecting initial costs, maintenance schedules, replacement intervals, and overall system reliability. Facilities that invest in premium coating technologies typically achieve superior long-term value despite higher upfront costs through reduced maintenance labor, fewer replacement cycles, and improved operational performance. The total cost of ownership analysis consistently favors advanced coating systems for most outdoor applications.

Environmental challenges facing outdoor mirrors continue intensifying as climate patterns shift toward more extreme weather events, increased UV exposure, and greater temperature variations. Coating technologies must address these evolving challenges while maintaining compatibility with existing installation practices and economic constraints. The most successful coating systems demonstrate superior performance across multiple environmental stressors rather than optimizing for single environmental factors.

Fundamental Coating Science and Material Properties

Modern weather-resistant coatings rely on advanced polymer chemistry that creates molecular-level barriers against environmental intrusion while preserving optical transmission characteristics essential for mirror functionality. These materials represent significant advances over traditional protective approaches through engineered molecular structures that provide specific resistance to moisture, chemicals, and physical wear. Understanding the fundamental science behind these materials enables informed selection and application decisions.

Polymer backbone chemistry determines the primary performance characteristics of weather-resistant coatings through molecular structure optimization that balances flexibility, adhesion, and environmental resistance. Fluoropolymer systems provide exceptional chemical resistance and UV stability but may require specialized application techniques and higher curing temperatures. Silicone-modified polymers offer superior temperature cycling resistance and maintain flexibility across extreme temperature ranges while providing good adhesion to glass substrates.

Cross-linking density directly influences coating durability and environmental resistance through molecular network formation that creates three-dimensional polymer structures. Higher cross-linking densities generally provide superior chemical resistance and mechanical durability but may reduce coating flexibility and impact resistance. Optimal cross-linking levels depend on specific application requirements and environmental exposure conditions.

Additive chemistry enhances base polymer performance through incorporation of specialized compounds that provide targeted protection against specific environmental threats. UV stabilizers prevent polymer degradation from solar radiation exposure, while hydrophobic agents reduce water absorption and improve moisture resistance. Anti-oxidants protect against chemical degradation from atmospheric pollutants and industrial chemicals commonly found in outdoor environments.

Film thickness optimization balances protection effectiveness against application costs and optical performance requirements. Thicker films generally provide superior environmental protection but may affect optical clarity and increase material costs. Professional applications typically target film thickness between 25-75 microns depending on environmental severity and performance requirements.

Adhesion promotion systems ensure reliable bonding between protective coatings and mirror substrates throughout extended environmental exposure. Silane coupling agents create chemical bonds with glass surfaces while providing compatibility with organic coating systems. Proper adhesion is critical for long-term performance since coating delamination typically leads to rapid mirror degradation.

Advanced Coating System Architectures

Contemporary weather-resistant coating systems employ multi-layer architectures that optimize protection through specialized layer functions rather than relying on single-layer approaches. These sophisticated systems provide superior performance through engineering that addresses specific environmental challenges at different protection levels. The most effective architectures balance complexity against performance benefits to achieve optimal cost-effectiveness.

Primer layer systems provide foundation adhesion and surface preparation that ensures reliable bonding throughout environmental exposure cycles. These layers often incorporate corrosion inhibitors and adhesion promoters that create stable interfaces between mirror substrates and protective topcoats. Primer selection significantly influences overall system performance and must be matched to both substrate materials and topcoat chemistry.

Barrier layer technology creates impermeable films that prevent moisture and chemical infiltration while maintaining optical transparency. Advanced barrier layers may incorporate nano-scale materials that provide molecular-level protection against specific environmental threats. These layers represent the primary defense against environmental degradation and require careful optimization for specific exposure conditions.

Topcoat formulations provide the final environmental interface and determine surface characteristics including cleanability, scratch resistance, and optical properties. Modern topcoats may incorporate self-cleaning technologies, anti-graffiti properties, and enhanced UV resistance that extends overall system life. Topcoat selection affects both performance and maintenance requirements throughout system service life.

Functional additive integration enables specialized performance characteristics through incorporation of materials that provide specific benefits beyond basic environmental protection. Hydrophobic additives create water-shedding surfaces that reduce cleaning requirements and prevent water spot formation. Anti-static additives reduce dust accumulation that can degrade optical performance over time.

Compatibility engineering ensures that multi-layer systems function effectively without interlayer adhesion problems or chemical incompatibilities that could compromise performance. Professional coating systems undergo extensive compatibility testing to verify long-term stability and performance retention. Proper system design prevents coating failures that result from chemical interactions between different layers.

Environmental Resistance Mechanisms

Weather-resistant coatings protect outdoor mirrors through multiple resistance mechanisms that address specific environmental threats commonly encountered in outdoor installations. Understanding these mechanisms enables proper coating selection and application for specific environmental conditions while ensuring optimal protection effectiveness. The most successful coating systems incorporate multiple resistance mechanisms rather than relying on single protection approaches.

UV radiation resistance prevents polymer degradation that occurs when high-energy solar radiation breaks chemical bonds in coating materials. Advanced UV stabilizer chemistry absorbs harmful radiation and converts it to harmless heat energy that dissipates without damaging the polymer structure. Effective UV protection often determines overall coating service life in high-exposure environments.

Moisture barrier properties prevent water infiltration that can cause mirror backing corrosion, substrate degradation, and optical performance loss. Modern barrier systems may achieve water vapor transmission rates below 0.1 g/m²/day through optimized polymer chemistry and film structure. Moisture protection becomes particularly critical in humid climates and marine environments.

Chemical resistance protects against degradation from atmospheric pollutants, acid rain, salt spray, and industrial chemicals that commonly attack outdoor installations. Fluoropolymer chemistry provides exceptional resistance to most chemical threats while maintaining long-term stability. Chemical resistance requirements vary significantly based on installation location and local environmental conditions.

Temperature cycling resistance maintains coating integrity through repeated expansion and contraction cycles that occur with daily and seasonal temperature variations. Proper polymer selection and formulation ensures that coatings remain flexible at low temperatures while maintaining strength at elevated temperatures. Temperature cycling represents one of the most demanding environmental stressors for outdoor coatings.

Abrasion resistance protects against physical wear from wind-borne particles, cleaning activities, and incidental contact that can degrade coating surfaces over time. Advanced coating formulations incorporate hard particle additives or cross-linking systems that provide superior wear resistance. Abrasion protection becomes particularly important in dusty environments or high-traffic areas.

Application Technologies and Process Control

Professional coating application requires sophisticated process control that ensures uniform film formation, proper adhesion, and optimal curing to achieve specified performance characteristics. Application technology selection affects both coating performance and installation costs through requirements for specialized equipment, environmental controls, and quality assurance procedures. The most successful installations employ application technologies matched to specific coating systems and site conditions.

Surface preparation protocols establish foundation conditions necessary for reliable coating adhesion and long-term performance. Proper cleaning removes contaminants that could interfere with bonding while surface profiling creates mechanical adhesion enhancement. Professional applications typically include multi-stage cleaning procedures that address oils, salts, oxidation products, and other contaminants commonly found on mirror surfaces.

Application environment control ensures optimal curing conditions through temperature, humidity, and cleanliness management during coating application and initial cure periods. Most advanced coatings require specific environmental conditions to achieve optimal film formation and performance characteristics. Controlled application environments prevent contamination and ensure consistent coating quality.

Film thickness monitoring provides real-time feedback during application to ensure uniform coverage and proper film build-up across entire mirror surfaces. Electronic thickness gauges enable immediate verification of coating thickness while allowing adjustments to application parameters when necessary. Consistent film thickness directly affects both performance and appearance of finished installations.

Curing optimization determines final coating properties through controlled chemical reactions that create cross-linked polymer networks. Advanced curing systems may employ UV radiation, elevated temperatures, or catalytic reactions to achieve optimal polymer properties. Proper curing is essential for achieving specified performance characteristics and requires careful control of curing parameters.

Quality assurance testing verifies that applied coatings meet specification requirements through standardized test procedures that evaluate adhesion, thickness, appearance, and initial performance characteristics. Professional installations include comprehensive testing that provides documentation of coating quality and performance compliance. Quality assurance prevents installation failures and supports warranty coverage.

Performance Testing and Validation Methodologies

Comprehensive performance validation ensures that weather-resistant coatings provide specified protection levels throughout their intended service life. Testing methodologies combine accelerated laboratory procedures with real-world exposure studies to predict long-term performance and identify potential failure modes. Professional coating selection relies on validated performance data rather than manufacturer claims or limited testing.

Accelerated weathering testing simulates years of environmental exposure through controlled laboratory conditions that intensify specific environmental stressors. UV exposure chambers, humidity cycling equipment, and temperature cycling systems enable prediction of long-term performance within practical testing timeframes. Standardized test procedures provide comparable results between different coating systems.

Salt spray resistance testing evaluates coating performance in marine environments and areas subject to road salt exposure through controlled salt fog exposure procedures. These tests identify coating systems suitable for coastal installations and winter maintenance areas where salt exposure represents a primary environmental threat. Salt spray testing often reveals coating failures not apparent in other test procedures.

Thermal shock evaluation assesses coating resistance to rapid temperature changes that occur in outdoor environments through cycling between extreme temperatures. These tests identify potential failure modes related to differential thermal expansion and help predict coating performance in climates with large temperature variations. Thermal shock resistance often determines coating suitability for extreme climate applications.

Chemical resistance evaluation exposes coatings to specific chemicals likely to be encountered in outdoor environments including acid rain, automotive exhaust, industrial emissions, and cleaning chemicals. These tests help predict coating performance in contaminated environments and support selection of appropriate systems for specific installation locations.

Field exposure studies provide real-world validation of laboratory test results through installation of test panels in actual service environments. Long-term field studies often reveal performance characteristics not apparent in accelerated testing while providing validation of laboratory predictions. Field studies support coating system optimization and provide confidence in performance predictions.

Maintenance Strategies and Lifecycle Management

Effective maintenance strategies maximize the service life and performance of weather-resistant coatings through proactive care that addresses environmental accumulation and minor damage before they compromise coating integrity. Professional maintenance approaches balance intervention frequency against coating durability to optimize lifecycle value while maintaining optimal mirror performance. The most successful maintenance programs address specific coating characteristics and environmental exposure conditions.

Cleaning protocol development establishes procedures that remove environmental contamination without damaging coating surfaces or reducing protection effectiveness. Proper cleaning materials and techniques preserve coating integrity while maintaining optical clarity essential for mirror functionality. Aggressive cleaning can damage coatings and reduce service life despite good intentions.

Inspection schedules enable early detection of coating degradation or damage that requires corrective action before major failures occur. Professional inspection protocols focus on areas most susceptible to environmental attack while documenting coating condition over time. Regular inspection data supports maintenance planning and coating system evaluation.

Damage assessment procedures evaluate coating failures and determine appropriate repair strategies that restore protection without compromising overall system integrity. Minor coating damage often responds to localized repair procedures while extensive damage may require complete recoating. Proper damage assessment prevents minor problems from becoming major failures.

Recoating strategies address end-of-life coating replacement through systematic approaches that optimize timing, surface preparation, and coating selection. Proper recoating extends mirror service life while providing opportunities to upgrade to improved coating technologies. Recoating timing affects both costs and performance outcomes.

Performance monitoring tracks coating effectiveness over time through systematic evaluation of protection levels, optical performance, and maintenance requirements. Performance data supports coating system optimization and provides validation of manufacturer performance claims. Monitoring results guide both immediate maintenance decisions and future coating selection.

Economic Analysis and Cost Optimization

Comprehensive economic analysis provides the foundation for coating system selection and maintenance strategy development through lifecycle cost evaluation that considers initial investment, maintenance requirements, and replacement intervals. Professional approaches balance coating performance against economic constraints to identify solutions that provide optimal value for specific applications and environmental conditions.

Initial cost analysis includes material costs, application expenses, and installation requirements that affect total project investment. Premium coating systems typically require higher initial investment but may provide superior long-term value through extended service life and reduced maintenance requirements. Proper cost analysis considers total project costs rather than material costs alone.

Maintenance cost projection estimates ongoing expenses related to cleaning, inspection, minor repairs, and periodic maintenance throughout coating service life. Advanced coating systems often reduce maintenance requirements and associated costs through superior environmental resistance and self-cleaning properties. Maintenance cost analysis requires understanding of specific site conditions and operational requirements.

Replacement interval analysis determines coating service life and replacement timing that affects long-term project costs and operational planning. Extended service life reduces annualized coating costs while providing operational benefits through reduced maintenance disruption. Service life projections must account for specific environmental conditions and maintenance practices.

Total cost of ownership calculations combine initial costs, maintenance expenses, and replacement intervals to determine overall project economics and support coating system selection. TCO analysis often reveals that premium coating systems provide superior economic value despite higher initial costs. Professional analysis includes all relevant cost factors rather than focusing on initial investment alone.

Return on investment evaluation quantifies benefits of advanced coating systems through reduced maintenance costs, extended service life, and improved operational performance. ROI calculations support business case development and budget approval for premium coating technologies. Professional ROI analysis accounts for both quantifiable benefits and operational improvements.

Future Developments and Emerging Technologies

The field of weather-resistant coating technologies continues advancing through materials science research, nanotechnology applications, and smart coating development that promise superior performance and new capabilities for outdoor mirror applications. Professional practitioners who understand emerging developments can anticipate future requirements and select technologies that accommodate advancing capabilities while optimizing current performance.

Nanotechnology applications enable coating enhancement through incorporation of engineered nanoparticles that provide specific performance benefits including self-cleaning properties, enhanced UV resistance, and superior barrier characteristics. Nano-enhanced coatings often provide performance improvements without significant cost increases while enabling new functionality previously unavailable.

Smart coating technologies incorporate responsive materials that adapt to environmental conditions through reversible chemical or physical changes. These materials may provide enhanced protection during severe weather while maintaining optimal optical properties during normal conditions. Smart coatings represent an emerging technology with significant potential for outdoor applications.

Bio-inspired coating development draws from natural systems that provide superior environmental resistance through engineered surface structures and chemical compositions. These approaches may enable new performance characteristics while using environmentally friendly materials and processes. Bio-inspired technologies often provide multiple benefits through integrated approaches rather than single-function protection.

Sustainable coating chemistry addresses environmental concerns through development of low-impact materials and processes that provide equivalent or superior performance compared to traditional systems. Sustainable approaches may reduce manufacturing environmental impact while maintaining or improving coating performance characteristics.

Integration capabilities enable coating systems that provide multiple functions beyond environmental protection including energy generation, sensing capabilities, and communication functions. Integrated coating systems may provide superior overall value through multiple benefits that justify premium investment costs while simplifying installation requirements.

The mastery of weather-resistant coating technologies for outdoor mirror applications represents a critical professional competency that combines materials science understanding with practical application knowledge. Professionals who develop expertise in this field can create installations that provide superior performance, extended service life, and optimal economic value while addressing evolving environmental challenges and operational requirements. The continuing advancement of coating technologies ensures that this field will remain both technically challenging and economically rewarding for dedicated practitioners.

Looking for a custom convex mirror manufacturer or supplier? Struggling to find the right factory to bring your vision to life? We’ve got you covered! At our place, we craft top-quality convex mirrors with precision and care. Big or small, your needs are our mission. Let’s launch your mirror project and take your product line to the next level! Click here to contact