(Enhancing Operational Safety with Visibility) In the fast-paced environment of industrial warehouses and logistics hubs, safety, coordination, and real-time visibility are paramount. Every square meter of a warehouse or freight terminal operates with heavy machinery, palletized goods, and foot traffic all moving simultaneously. In such a setup, blind spots become accident hotspots—posing risks to personnel, assets, and operational efficiency. Convex mirrors, with their wide-angle visibility and passive functionality, serve as a cost-effective yet highly reliable safety solution in industrial warehousing and logistics.

Improving Forklift Navigation and Aisle Monitoring

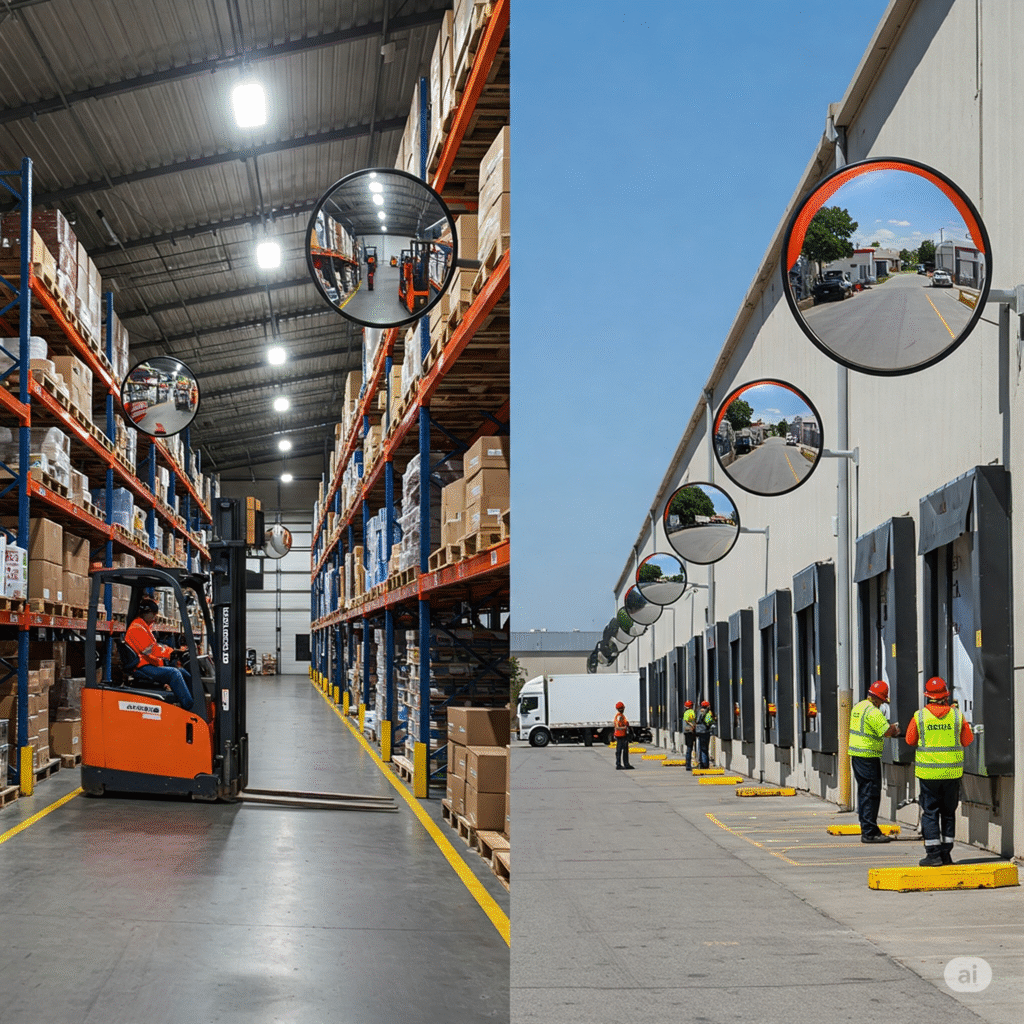

Forklifts are vital for material handling in most warehouse environments, often maneuvering through narrow aisles, tight corners, and intersections between shelving units. These areas usually lack a clear line of sight, increasing the likelihood of collisions or near-misses. Convex mirrors, when strategically mounted at corners and aisle junctions, give operators a panoramic view of intersecting paths. This allows drivers to anticipate movement, slow down, or stop before entering a blind zone—drastically reducing the chance of accidents and improving overall traffic flow inside the facility.

Monitoring Loading Bays and Docking Points

Loading docks are one of the busiest—and riskiest—zones in a warehouse. Trucks back into tight spaces, often with limited driver visibility, while warehouse workers simultaneously load or unload cargo. Installing convex mirrors above or around the loading dock provides drivers and warehouse staff with a better view of their surroundings, minimizing the risk of back-over incidents or alignment errors. These mirrors also help supervisors monitor ongoing activity from a distance, ensuring safer and more coordinated operations during peak hours.

Preventing Pedestrian-Collision Hazards

In large warehouses and distribution centers, pedestrian walkways intersect with machinery paths, creating overlapping zones of risk. Employees may step into active zones unknowingly, or machinery operators may fail to see personnel walking near shelving units or blind turns. Convex mirrors installed at these crossing points act as a passive early-warning system, allowing both operators and pedestrians to see each other before contact. This is particularly important in facilities with limited floor markings or inadequate lighting.

Strategic Surveillance for Inventory and Security

Beyond safety, convex mirrors also contribute to inventory surveillance and security. By installing these mirrors at the ends of long aisles or in hard-to-monitor corners, security personnel can gain visual access to parts of the warehouse that may not be covered by CCTV. This visual extension helps deter unauthorized movement of goods and enhances accountability. While not a replacement for cameras, convex mirrors serve as a valuable addition to any industrial facility’s loss prevention strategy.

Adaptable Designs for Varied Environments

Convex mirrors used in industrial logistics are typically built using robust materials like polycarbonate or acrylic, housed in ABS or galvanized steel frames. These materials are impact-resistant, UV-stabilized, and often resistant to harsh cleaning chemicals or dusty environments—ensuring long-term clarity and durability. Their mounting brackets are adjustable and can be installed on poles, walls, or ceilings depending on the area of concern. This adaptability makes them suitable for a wide range of facilities—from refrigerated warehouses to open-air freight terminals.

Indoor vs Outdoor Use in Warehousing Operations

While most convex mirror use in warehousing is indoors, outdoor logistics areas such as container yards, truck staging zones, or inbound inspection zones also benefit from their installation. Outdoor-rated convex mirrors come with weatherproof coatings and anti-fog features, making them ideal for year-round use in loading areas exposed to rain, fog, or dust. These mirrors help drivers maintain alignment, reverse safely, and monitor pedestrian zones—especially in low-visibility conditions common in early morning or night operations.

Compliance and Workplace Safety Regulations

In many regions, occupational safety agencies encourage or mandate the use of visual aids to reduce workplace accidents. Installing convex mirrors in areas of frequent movement and potential collision aligns with health and safety best practices, helping businesses remain compliant. Insurance providers may also consider such installations as part of a facility’s risk reduction strategy, which can lower premiums and reduce liability in the event of an incident.

Cost Efficiency and Low Maintenance

Convex mirrors are one of the most cost-efficient safety solutions available to industrial buyers. Unlike active safety systems like sensors or camera installations, convex mirrors operate passively and do not require wiring, electricity, or calibration. Once installed, they need minimal maintenance—just routine cleaning to remove dust or condensation. This makes them particularly attractive for large-scale logistics facilities with multiple hazard zones where replicating expensive tech solutions is not feasible across all areas.

Procurement Considerations for Industrial Buyers

For purchasing managers and safety officers, selecting the right convex mirrors involves evaluating mirror diameter, curvature radius, and mounting type. Larger diameter mirrors offer broader coverage, while tighter curvatures provide more focused visibility. Depending on aisle width or truck size, one may prefer 60cm or 80cm options with ceiling-mounted brackets. Vendors that specialize in industrial-grade mirrors can offer guidance on placement strategy and installation methods suited for B2B-scale deployment. Ordering in bulk, particularly for multi-site operations, also ensures cost efficiency and standardization across facilities.

Conclusion: (Integral Component of Modern Warehousing)

In a warehousing and logistics landscape where time, precision, and safety define success, convex mirrors serve as silent sentinels. They enhance visibility, reduce operational risks, and promote safe navigation across machinery, vehicles, and personnel. Whether retrofitting an existing facility or designing a new warehouse layout, including convex mirrors in the safety plan is a decision backed by both logic and regulation. For industrial buyers, logistics managers, and safety consultants, these mirrors are not just accessories—but essential components of a responsible and forward-thinking operational strategy.

Looking for a custom convex mirror manufacturer or supplier? Struggling to find the right factory to bring your vision to life? We’ve got you covered! At our place, we craft top-quality convex mirrors with precision and care. Big or small, your needs are our mission. Let’s launch your mirror project and take your product line to the next level! Click here to contact