Traffic cones are a cornerstone of road safety and temporary traffic control systems used in roadworks, construction sites, logistics yards, airports, and parking zones. With multiple types of cones available in the market, two of the most widely used materials are PVC (Polyvinyl Chloride) and rubber. Understanding the long-term performance, durability, cost-efficiency, and usability of PVC and rubber cones is essential for procurement teams, safety managers, wholesalers, and global traffic management solution providers. This article presents a comprehensive analysis of PVC vs rubber traffic cones, focusing on their suitability for long-term B2B applications.

Material Composition and Flexibility

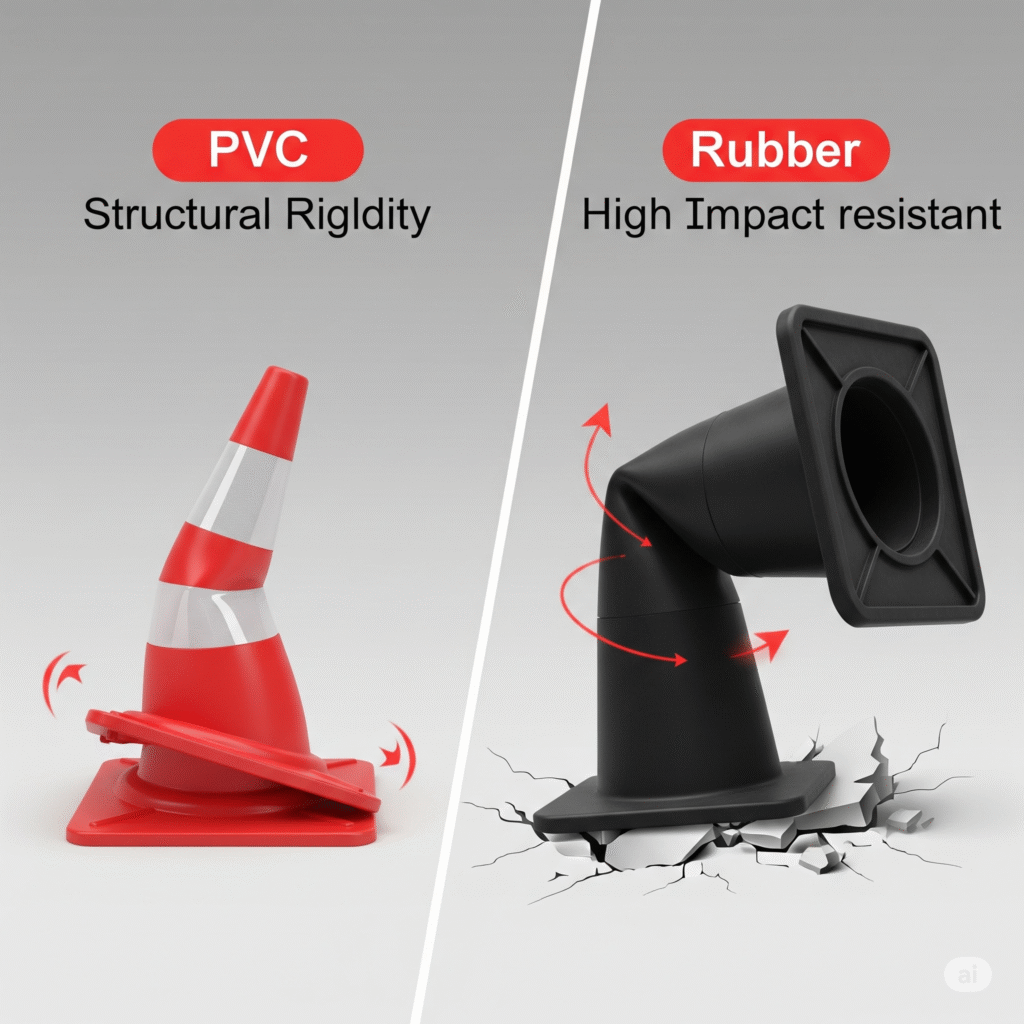

PVC cones are molded from thermoplastic polymers, making them lightweight and moderately flexible. These cones can bend slightly under pressure and typically return to their original shape. Their color is usually embedded during the manufacturing process, offering vibrant visibility even under various lighting conditions. However, extended sun exposure may cause them to fade over time.

Rubber cones, by contrast, are made from recycled or virgin rubber materials. These cones are significantly more flexible and impact-resistant. When subjected to vehicle impact or high-pressure contact, rubber cones tend to bend and rebound without sustaining cracks or deformation. This extreme flexibility gives rubber cones an advantage in rough and high-impact environments such as highway shoulders or industrial zones.

Weight and Wind Resistance

One of the critical concerns for traffic safety cone users in outdoor environments is the cone’s ability to resist displacement caused by wind or passing vehicles. PVC cones are generally lighter, which makes them easier to handle and deploy, especially during quick-response scenarios or temporary lane closures. However, their light weight also makes them more susceptible to tipping over in windy or fast-moving vehicle zones unless weighted bases are added.

Rubber cones naturally offer more weight and stability due to their dense construction. This makes them ideal for long-term deployments in open areas, highways, logistics yards, or elevated sites where wind is a major concern. Their ability to remain firmly in place reduces the frequency of manual repositioning, offering long-term operational efficiency.

Durability and UV Resistance

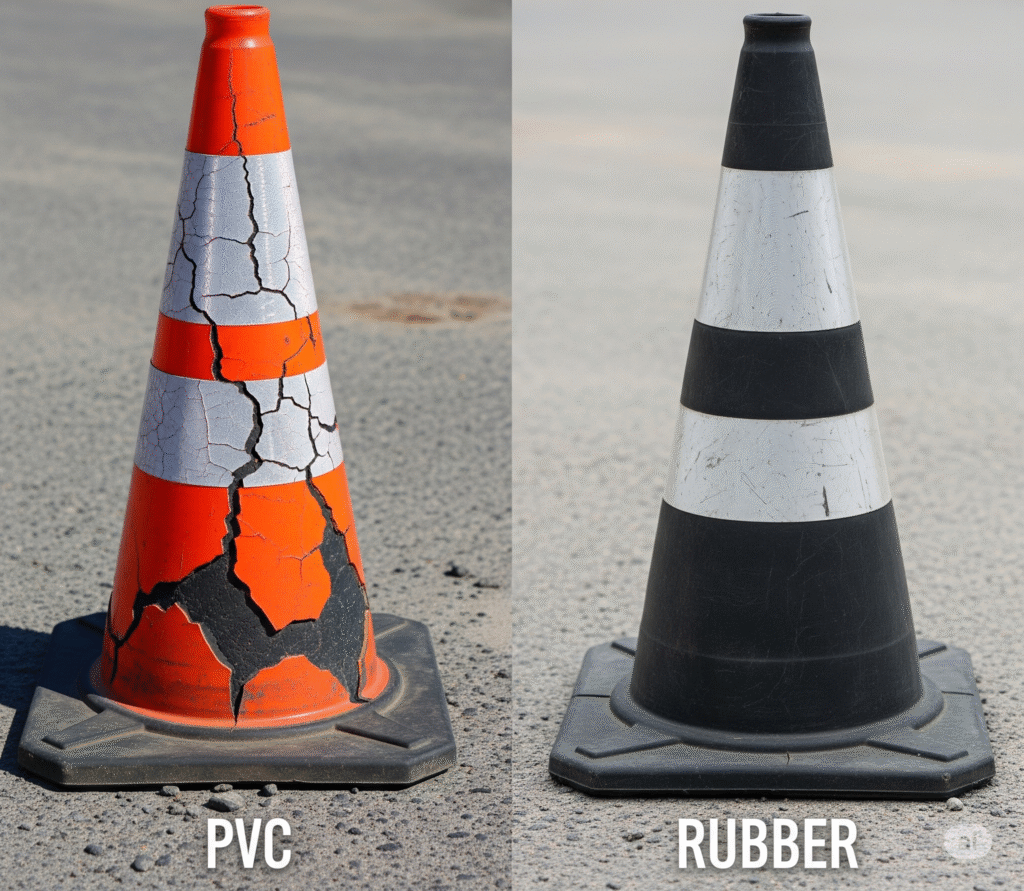

In B2B procurement for traffic control devices, durability plays a critical role in determining the cost-effectiveness of any product. PVC cones have moderate resistance to harsh weather but are more prone to wear and tear from repeated vehicle impacts, UV exposure, and low temperatures. Over time, these cones may become brittle or develop cracks, particularly in cold regions.

Rubber cones are known for their ruggedness. They perform well in a broad temperature range and are naturally UV resistant. Even after prolonged outdoor exposure, they maintain their flexibility and structural integrity. This makes rubber cones a preferred choice for permanent or semi-permanent traffic control installations, especially in regions with extreme weather conditions.

Reflective Band Integration and Visibility

Both PVC and rubber cones support high-visibility features, such as reflective collars and colored banding. PVC cones generally have reflective strips glued or heat-sealed to the surface, offering high reflectivity for night-time visibility. However, over time, these strips can peel or degrade, especially in dusty or wet environments.

Rubber cones, while sometimes lacking the color vibrancy of PVC, typically retain reflective bands more securely due to the textured and flexible surface. Some models are manufactured with integrated reflective bands that are built into the mold or attached using industrial adhesives designed for high-durability use. In terms of long-term night visibility, rubber cones generally provide more consistent performance with less maintenance.

Cost Considerations for Bulk Buyers

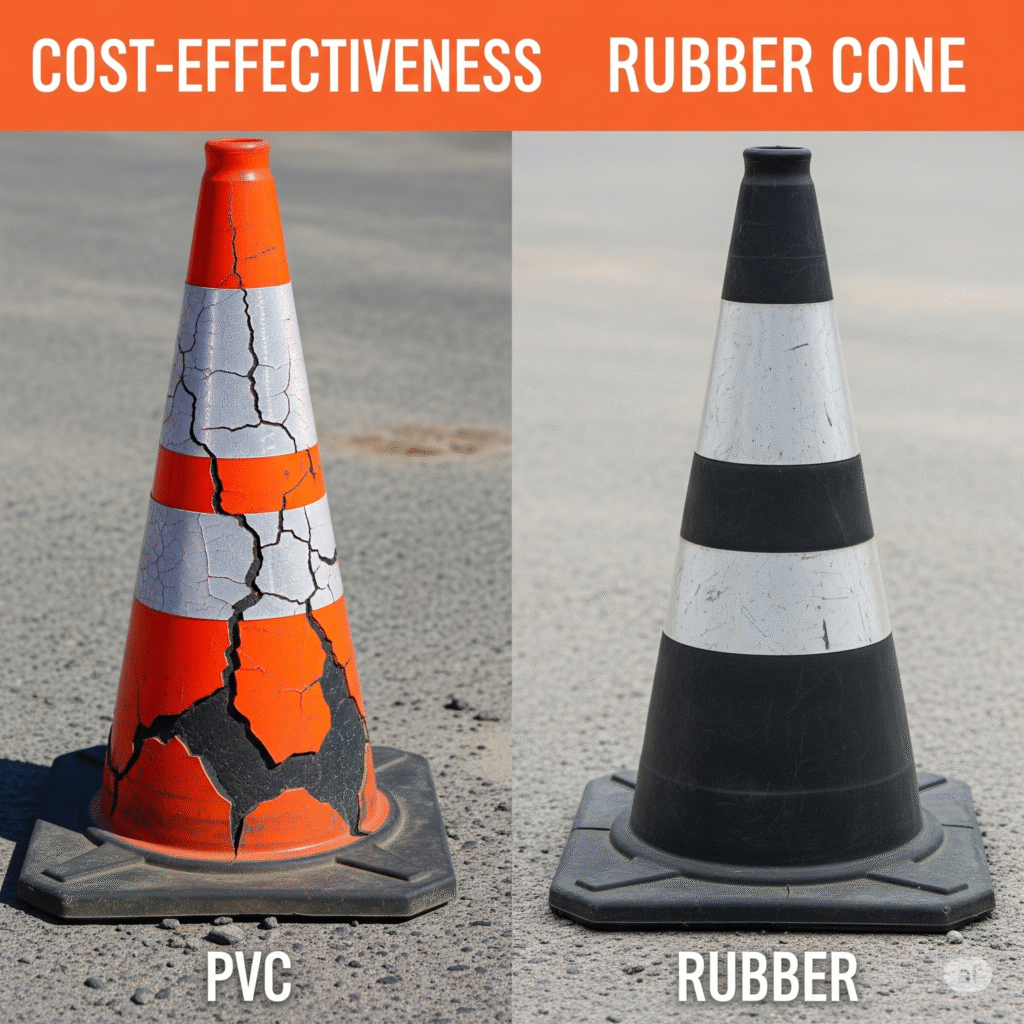

From a manufacturing and initial purchasing perspective, PVC traffic cones are more economical. Their production process is less resource-intensive, and they are widely available in standard dimensions ranging from 45 cm to 90 cm. For government tenders, short-term projects, or large-scale event management needs, PVC cones often provide the best cost-to-coverage ratio.

However, rubber cones, while more expensive initially, offer greater value over the lifecycle due to their durability and low replacement rates. For B2B buyers who manage logistics centers, construction zones, or road safety equipment across multiple geographies, investing in rubber cones can result in lower long-term procurement and maintenance costs.

Application Suitability in Industrial and Municipal Settings

PVC cones are better suited for temporary installations such as event management, sports areas, city traffic rerouting, or pedestrian guidance systems. Their lighter build makes them easier to store, transport, and deploy on the fly.

Rubber cones, on the other hand, are more effective in industrial zones, highway maintenance projects, and long-term construction operations. Their resistance to environmental stressors makes them the go-to solution for permanent safety layouts, freight yards, airports, and ports where daily wear and tear is unavoidable.

Environmental Sustainability and Recycling

Modern buyers are increasingly prioritizing sustainability in procurement decisions. PVC is recyclable, but its recycling process is more complex and limited due to the presence of additives and plasticizers. Improper disposal of PVC cones can contribute to landfill waste.

Rubber cones, often made from recycled rubber, offer a circular economy solution. Many manufacturers collect worn-out rubber products and reprocess them into new cones, thus reducing carbon footprint and enhancing sustainability. For companies aiming to meet ESG goals, rubber cones present a greener alternative.

Conclusion (Choosing the Right Cone for Long-Term Use)

In summary, both PVC and rubber traffic cones have distinct strengths and limitations. For short-term, low-budget, and lightweight traffic control needs, PVC cones are practical and economical. For high-impact environments, long-term outdoor use, and industrial traffic management systems, rubber cones offer unmatched durability, wind resistance, and overall ROI.

B2B buyers, wholesalers, and global safety product suppliers must consider the application environment, total lifecycle cost, and sustainability factors before choosing between PVC and rubber cones. The right selection not only ensures road safety compliance but also contributes to efficient resource management and long-term operational success.

Looking for a custom traffic cones manufacturer or supplier? Struggling to find the right factory to bring your vision to life? We’ve got you covered! At our place, we craft top-quality traffic cones with precision and care. Big or small, your needs are our mission. Let’s launch your cones project and take your product line to the next level! Click here to contact