Critical Role of Visibility After Dark

As cities expand and infrastructure projects extend into late hours, night-time road safety becomes a growing concern for traffic management companies, municipal authorities, and construction contractors. Reflective traffic cones are among the most cost-effective yet indispensable tools in maintaining visibility and alerting motorists during low-light conditions. Whether deployed in urban construction zones, highway maintenance projects, or emergency response situations, these high-visibility markers serve as the first line of defense against collisions and confusion. This article explores the core features, material considerations, deployment strategies, and trade-specific relevance of reflective traffic cones in night-time safety planning.

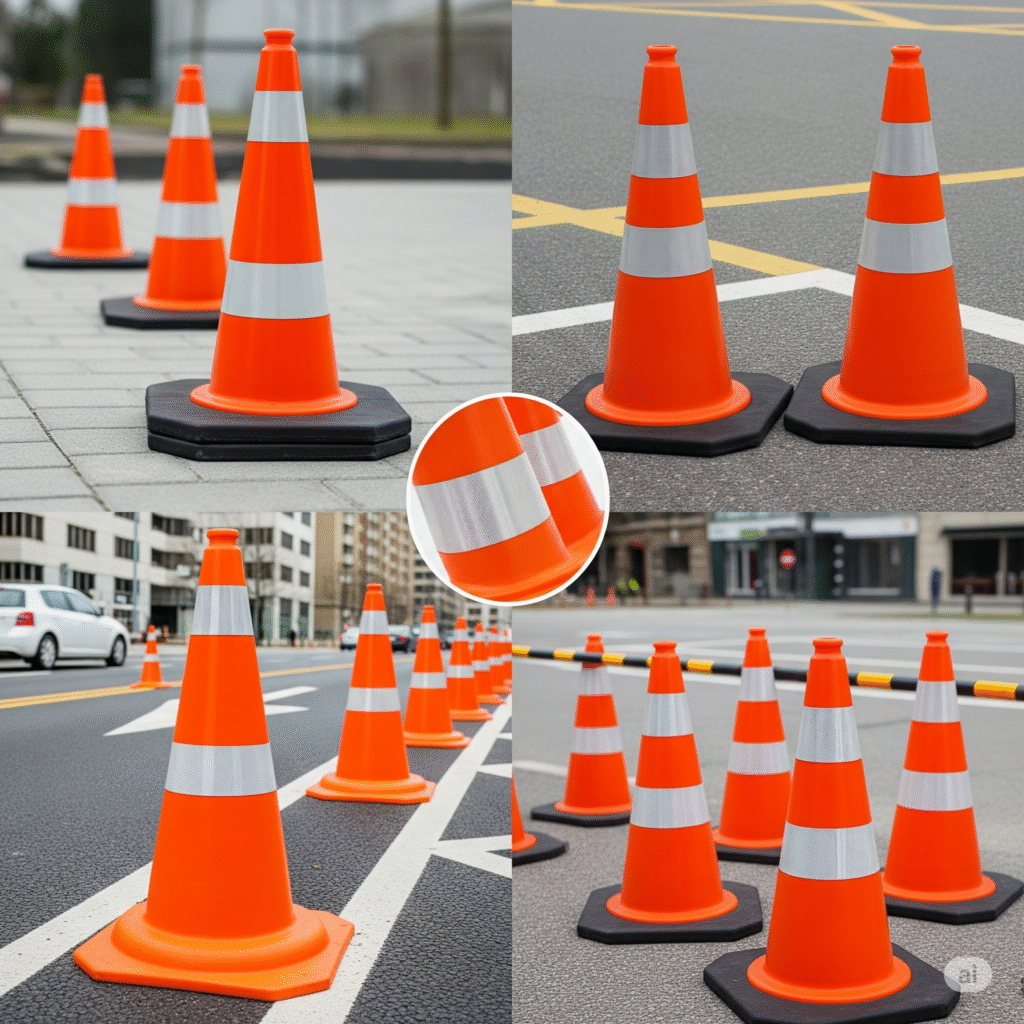

Night Visibility and Accident Prevention

Reflective traffic cones are engineered to enhance safety through visibility. At night, when headlights and ambient street lighting are the primary sources of illumination, cones fitted with reflective collars rebound light back toward the source, alerting drivers to lane deviations, work zones, or road hazards. This capability is especially critical in poorly lit rural areas, highways under renovation, or power outage scenarios.

Reflectivity ensures a cone’s visibility from distances of 500 feet or more, depending on the retro-reflective band quality. This extended visibility window is crucial for drivers to process warnings and adjust their course accordingly. Road safety planners and traffic control contractors prioritize such cones when preparing traffic management plans for projects occurring between dusk and dawn.

Material Selection for Night-Use Durability

Reflective traffic cones are generally made of two main materials: PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene). Each offers specific advantages for night-use environments. PVC cones are more flexible, making them resilient to run-overs or severe wind gusts. HDPE, on the other hand, offers excellent UV and weather resistance, ideal for long-term deployments where cones may be exposed to sun during the day and cold temperatures at night.

Regardless of the base material, the quality of the reflective band is a critical component. Engineers and safety product specifiers often look for Class 1 or Class 2 prismatic reflective sheeting that meets ANSI or ASTM D4956 standards. These bands must retain their reflective properties even after multiple cleaning cycles or prolonged UV exposure. For this reason, sourcing cones from verified ISO-certified manufacturers is essential for public infrastructure tenders or large-scale B2B orders.

Weight and Base Stability in Low-Light Conditions

Night-time road work often takes place when traffic volumes are low but vehicle speeds are high. This makes cone stability non-negotiable. Manufacturers often embed weight at the cone base or provide stackable rubberized bases to prevent tipping from wind pressure or passing vehicles.

Buyers should assess the base width and weight distribution before placing bulk orders for reflective traffic cones. A 28-inch cone with a 7–10 lb weighted base typically meets state DOT regulations and is preferred by contractors managing large night paving or milling projects. Cones with detachable bases are also advantageous for shipping and storage in commercial applications.

Integration With Additional Warning Systems

Modern reflective traffic cones can be enhanced with integrated accessories for even higher visibility and utility. For example, many cones are now designed with grooves or slots to fit LED flashing lights. These lights further improve nighttime effectiveness by pulsing red or amber flashes to approaching motorists.

Some traffic management companies also integrate GPS-enabled sensors that can trigger alerts to a central monitoring system if a cone is displaced. This level of digital integration is increasingly seen in high-budget infrastructure or smart city projects. B2B buyers in urban planning, logistics management, or national road safety programs are actively seeking such smart cones to ensure greater coverage and risk management.

Compliance With National and International Standards

Purchasing reflective traffic cones for regulated projects requires alignment with national road safety standards. In the U.S., cones must comply with the Manual on Uniform Traffic Control Devices (MUTCD). In the EU, EN13422 governs cone dimensions, reflectivity, and testing parameters. Buyers from global ports, airport authorities, or intergovernmental highway projects should ensure the selected supplier’s certifications match local project criteria.

Exporters and international procurement departments must be able to provide certification documents, test reports, and batch production numbers for customs clearance and project audits. This creates a market opportunity for manufacturers who not only meet compliance standards but also offer end-to-end documentation for cross-border trade.

Custom Branding for B2B Applications

For large-scale buyers such as contractors, airport authorities, or port safety managers, custom branding on reflective traffic cones can aid in logistics tracking, theft reduction, and brand promotion. Many suppliers offer hot-stamped logos or QR codes directly on the cone body. This is particularly important in private B2B projects where multiple contractors operate at a single location, and asset identification is essential.

Commercial buyers also value custom color options beyond the standard orange. Fluorescent lime, blue, and red cones may be preferred depending on region-specific regulations or to distinguish among work zones. A manufacturer’s ability to offer small-batch customization is often a deciding factor in high-value B2B orders.

Storage, Handling, and Deployment Considerations

Night-time deployment often means fast setup and teardown operations. Reflective traffic cones must be stackable, lightweight for transport, and rugged enough to withstand repeated handling. Traffic control companies working on emergency response contracts often store cones in quick-deploy carts or modular crates for rapid positioning on highways or accident zones.

UV-resistance and weather durability should also be considered for cones stored outdoors. Over time, substandard cones can fade or delaminate, reducing their reflectivity and putting workers at risk. Contract clauses for night roadwork typically require cones to maintain at least 80% reflectivity across a 12-month project cycle. Thus, vendors who offer long-warranty cones with weather-sealed reflective banding hold a competitive advantage in the commercial market.

Sustainability and Recycling Benefits

While safety remains paramount, modern B2B procurement increasingly includes sustainability clauses. Many governments and corporations seek vendors whose traffic cones are made from recycled plastic or rubber. Some manufacturers use post-consumer or post-industrial waste materials for both the cone body and base, helping clients meet ESG (Environmental, Social, Governance) targets.

Recyclable cones can also be collected at the end of long projects and returned for remanufacturing. For high-volume buyers, this offers a win-win opportunity to save cost while complying with local green procurement policies. Traffic safety product resellers targeting institutional or public-sector buyers can leverage this feature as a strong selling point in tenders and RFPs.

Conclusion: Essential Safety Asset in Night-Time Projects

Reflective traffic cones are more than just brightly colored markers—they are engineered safety tools that protect lives and enable efficient traffic flow in hazardous night-time environments. Their material quality, reflective strength, base design, and accessory compatibility all contribute to their effectiveness on the road. For B2B buyers involved in infrastructure, transport, construction, or public safety, sourcing the right reflective cone is a strategic investment.

Whether your organization needs 1,000 cones for a city-wide highway upgrade or 50 premium units for an airport runway refurbishment, knowing what to look for ensures regulatory compliance, worker safety, and cost efficiency. Manufacturers and global suppliers who prioritize durability, visibility, and customization will remain the preferred partners in night-time road safety deployments.

Looking for a custom traffic cones (With Night-Time Road Safety) manufacturer or supplier? Struggling to find the right factory to bring your vision to life? We’ve got you covered! At our place, we craft top-quality traffic cones with precision and care. Big or small, your needs are our mission. Let’s launch your cones project and take your product line to the next level! Click here to contact